EXDIN Solutions: a revolution in the food sector

The food sector is one of the most demanding areas to run business, as it has to align the needs of a producer, keen on the competitive product prices and longer shelf life, with the needs of the consumers who set a great store by the high quality of the products, nutrients, and the aesthetic values. These needs are perfectly well matched by EXDIN Solutions, which unfurled its wings with the support of the Kraków Technology Park Seed Fund.

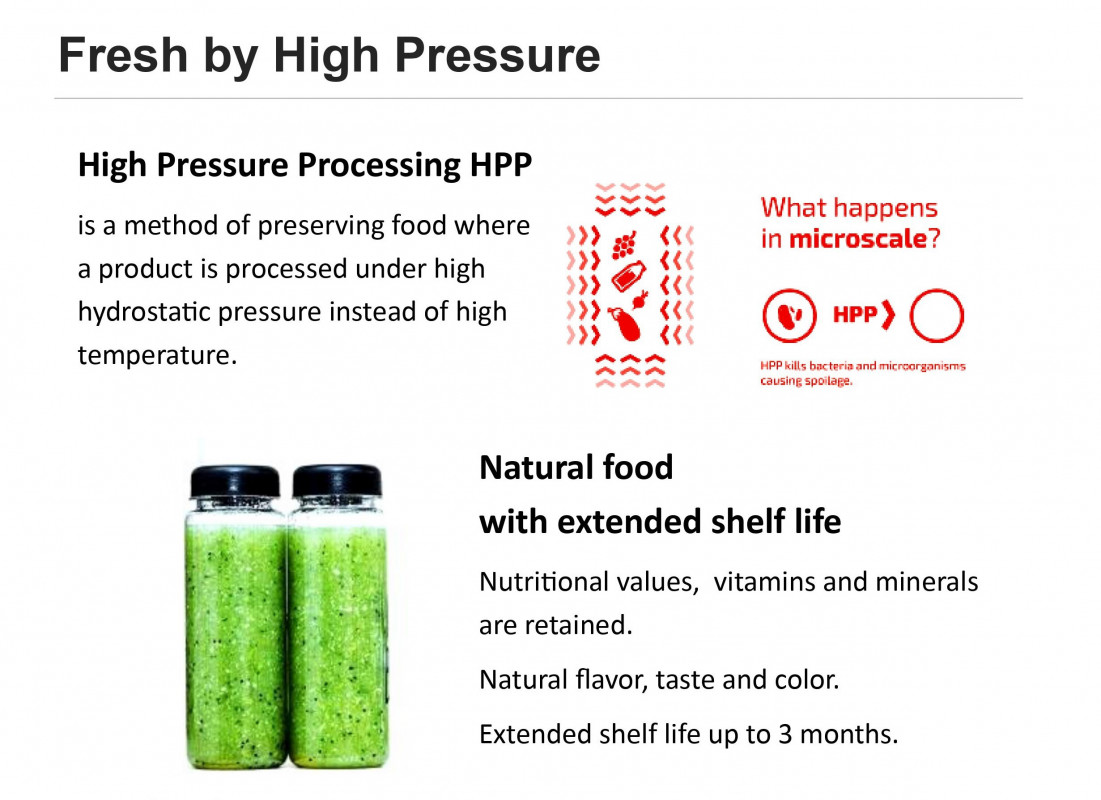

Known for ages, thermal processing is a widespread way of processing food: to make the victuals last longer, you subject them to high temperature. The process greatly increases safety, as temperature kills bacteria and extends the shelf life. However, that manner of processing food has a fundamental drawback: high temperature changes the nutritive value, and the taste and colour of a product, which takes away most of the qualities customers expect in their vegetables.

The challenge for the food sector was answered by the team of EXDIN Solutions, who revolutionised the approach to food processing.

A powerful position in the competition for the funds

At the outset of the company’s operation, the concept, the well-designed prototypes, and the understanding of the technology and awareness of the unique qualities of the solution gave EXDIN Solutions a strong position in the competition for funds for development. Their perfectly well prepared business concept made a powerful impression on the representatives of the Kraków Technology Park (KPT) Seed Fund.

“In our fund, we were somewhat discouraged by start-ups building successive applications, and began to look for projects that would develop somewhat trickier technologies with higher entry barriers for competitors. That was the time when we invested into Coolomat, Husarion, Synerise, and into EXDIN Solutions precisely. The, relatively small, financial assets involved made it possible to start a company, build the core team, order intellectual property issues, develop the virtual prototype, submit an application to the Szybka Ścieżka (Quick Path) programme, and find a fully private equity investor, who took over the further financing of the project. The KPT Fund used that opportunity for exiting the company, recognising that it had already played its role and, last but not least, achieved the assumed rate of return. EXDIN Solutions was certainly one of those companies that persuaded us to invest into ambitious R&D-based projects, which we are now successfully doing as part of our successive fund, INNOventure”, Marcin Bielówka, CEO ofINNOventure, at the time the president of the seed fund, explained.

“We were familiar with the Kraków Technology Park back from the time when we worked at the Kraków University of Technology (PK). It was a natural option for us to go and see what the KPT offers to young entrepreneurs. In this way we met their Seed Fund that made a very positive impression on us at the first contact already. While working together, we had substantial freedom to act, which is necessary for the proper development of a technology business. Errors are part and parcel of operation of young companies, and actually necessary to give the company a lasting foundation, which is why the knowledge of the Fund was very important for us: the understanding of how you build your company’s know-how. It is crucial to draw conclusions from your mistakes as quickly as possible and never let them recur”, CEO Grzegorz Widłak explained.

Nevertheless, a fantastic business plan and a revolutionary idea did not come from nowhere. The EXDIN Solutions team, hailing from two Kraków universities – the Kraków University of Technology and the AGH University of Science and Technology – are people who gained their first hands-on experience abroad.

Dr Grzegorz Widłak spent the first years of his professional activity in Norway, working for the largest technology companies. There, he gained experience and know-how connected to the modelling, design, and production of high pressure equipment in heavy industry.

“We designed many unique constructions. Nearly each one was a challenge for us professionally, due to the extreme requirements on load and conditions at which they had to work. The devices we co-created at the time work on the Barents Sea, and on the North Sea. That was a great and very well paid job that gave us plenty of professional accomplishment, however, there was that creative restlessness in our heads all the time. After a few years of working in Norway, we learnt that our Swedish friends were working on a technology of ultrahigh pressures, reaching 6000 bars. That is six times the pressure on the bottom of the Mariana Trench. It generates powerful forces, comparable to those that a space rocket generates at launch. Our sector may not be rocket science, yet it is close”, Grzegorz Widłak, CEO of EXDIN Solutions explained.

The idea that originated at lunch

“We met a handful of Swedes who were developing the HPP (High-Pressure Processing) technology. At another lunch, while discussing the concept, we had an idea how to design and manufacture faster and more effective devices that are key for the development of that technology”.

The whole concept of the company focuses around the use of high pressures for making food last longer – that is the HPP, and on the construction of the equipment dedicated to the food industry.

The technology developed by EXDIN Solutions allows retention of the valuable flavours and the nutritive value, as high pressure does not destroy such little particles as vitamins, while it liquidates the pathogenic food-damaging microorganisms, for example, salmonella. This makes it possible to obtain a product that is as healthy as the original produce, with taste and colour unchanged yet a longer shelf life. The process also offers real benefits to food producers.

The food sector: a hard nut to crack

You hardly ever associate the food sector with high and modern technologies. And yet it certainly should: manufacturing requires very high-level of technology, and the input material in Poland is of highest quality, which gives EXDIN Solutions a vast potential for growth.

Compared to other branches of the industry that make use of high-pressure technologies, this sector offers the greatest challenges, as it not only calls for the highest pressures but also requires that they are frequently repeated. Only companies with a very high engineering potential are capable of meeting such expectations.

Beyond doubt, EXDIN Solutions can boast such a potential. The company’s engineers designed high-pressure chambers protected by international patents. There are also a range of solutions that have are purposefully kept company secret, to avoid competition, as the company gathered its know-how and expertise for years.

“We didn’t know that sector before, but looking back in time we’ve got to like it very much. Nearly everyone sets a great store by natural foods, especially if they bring back the flavours of childhood. Yet this is still too little to get to know this sector well. Working for food consumers and manufacturers, we have become very familiar with that sector. We know what is important, what to pay attention to: that it is essential that you individually approach both each type of food and every food manufacturer. We know that you should never change nature and you need not improve it, all you can do is to reinforce it delicately, as it brings in the highest value.

“Starting our operation in 2015 we needed several years for the development of prototypes, scaling them up to industrial standards, and to prove our reliability in real production conditions. As far as the scope of the installations produced and their technological advancement are concerned, that was a very short period. Moreover, we developed local subcontractors and partners. All the components of our high-pressure devices are produced in Poland, which gives us quantifiable competitive advantages resulting from the highest quality of the products. Testing the devices we cooperated with fruit processors, including juice producers, which was a very good experience. Thanks to that, we decided to focus our activity on the fruit and vegetable sector, and adjust the equipment to its needs, as this is where we see the highest growth potential, while the practical demand for our solutions is confirmed by the producers themselves. Technologies of the HPP type, sometimes referred to as “minimum processing” as they do not alter the food but only extend is shelf life, offer the highest opportunity for success,” the CEO added.

You cooperate very closely with the client, and the HPP technology is adjusted to a specific food product. You first run tests on the product subjecting it to pressure processing known as Pascalisation (or bridgemanisation) at various pressure ratings and times. You then assess the organoleptic properties and test the physical and chemical properties as well as the microbiological safety of your food. That is the stage of testing the ideal conditions necessary to extend the “life expectancy” of just a bottle of natural juice, so that it has the highest quality and at the same time is safe for the consumer.

Technology on the market

“You work long term with a customer, and you have to develop what is known as the processing recipe for a specific product. The HPP technology has been known in Poland for a time, many producers are familiar with it, however and yet they never decided to implement it, as it was too expensive”, the CEO added.

EXDIN Solutions adjusted the solution to all business types: it can be used by large, small, and medium-sized enterprises alike, and the introduction of their technology will still pay. The company’s target sales model is global sales of devices and complete bottling lines making use of the HPP.

“We treat the Polish market as a particular testing ground for experimenting, as it is highly demanding. The food produce is of high quality, but food is cheap compared to other countries. Developing our technology, we analyse it so that the producer finds its introduction economically justified even in markets as competitive as the Polish”, Grzegorz Widłak explained.

At the same time agricultural produce of Poland is of very high quality compared e.g. to that of other European countries, which offers an opportunity to export highest quality food with longer shelf life at very attractive prices.

No devices using the HPP technology have been designed especially for the food sector anywhere in the world. The ones currently in use were adapted from the heavy industry. EXDIN Solutions developed the particulars of their equipment for the food sector, which lets the Polish company revolutionise the global food sector. This is not only a marketing slogan but also the result of hard work proved with patents and implementations.

“The plans for the future have not changed in many years, and they involve sales of high-profit margin products and technologies in the global market with strong entrance barriers for competitors, and they are persistently followed. Currently, we are working on projects situated in the countries of Western Europe, Russia, Turkey, and the United States. The reason for greatest personal pride is the success in building a very powerful team here in Poland, which shows that the key to an efficient hi-tech business are people with their knowledge and skills”, Grzegorz Widłak wrapped up.

EXDIN Solutions is certainly a company worth a closer look, as the ripples it makes are likely to acquire visibility soon.

EXDIN Solutions:

- manufactures HPP equipment designed for small and medium-sized enterprises producing organic food

- allows to introduce HPP technology that is cost-effective also on a smaller scale, which no competitive products have as yet offered

- helps also large producers to introduce automated HPP processes aligned with the idea of Industry 4.0

- is the only company capable of protecting the entire High Power Processing chain.

Go to website: https://www.exdinsolutions.com/

Contact

Krakowski Park Technologiczny sp. z o.o.

ul. Podole 60

30-394 Kraków

NIP 675-11-57-834